Pipeline Monitoring and Security

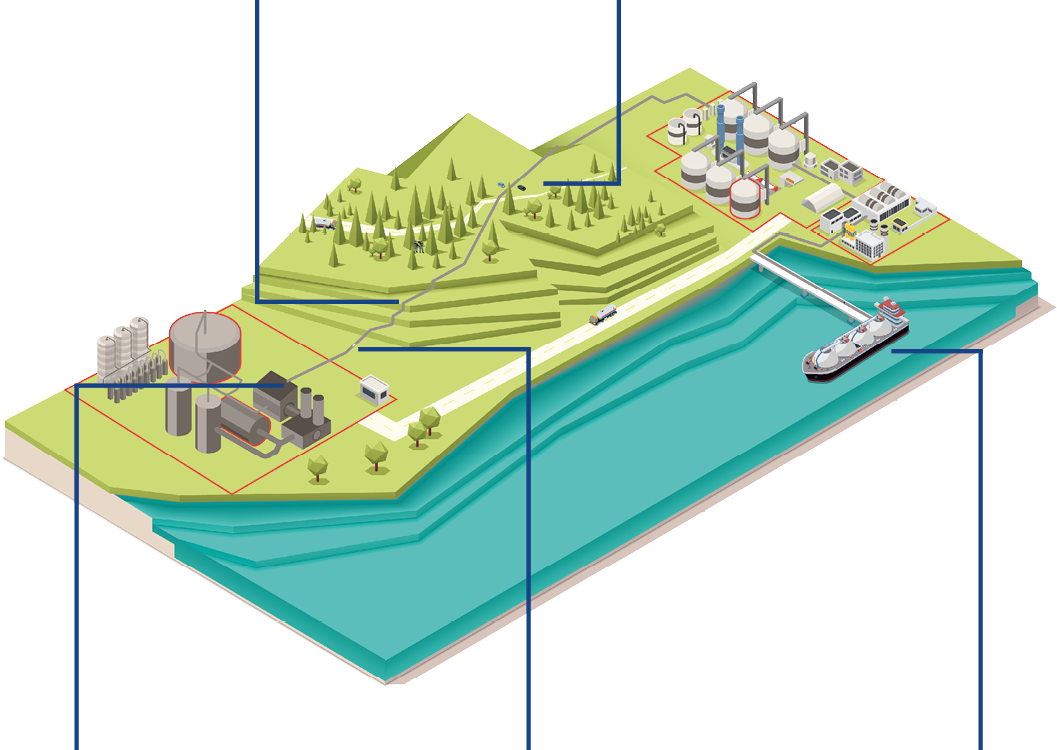

Bandweaver’s pipeline protection solutions includes both condition monitoring and Leak Detection System (LDS) based on Distributed Temperature Sensing (DTS) and Distributed Acoustic Sensing (DAS) systems, providing Third Party Interference (TPI) prevention.

To protect vital infrastructure that is particularly vulnerable to disruption, it is critical to keep assets such as pipelines secure. Whether the threats arise from accidental damage such as from 3rd party construction or deliberate interference, including terrorism, tapping or other malicious attack, there is a need to deploy a reliable and accurate solution.

By utilising the latest generation technology, operators can minimise environmental pollution or maximisation of uptime (through smart maintenance programs).Whether it is a remote long distance pipeline, an inner city pipe at risk of accidental damage or a process facility with condition monitoring requirements, Bandweaver’s unique and versatile range of systems can help.

Intelligent Insights

Location Accuracy

Rapid identification of incident location, therefore, enabling fast repair, reducing downtime and subsequent impact.

Increased Reliability

Superior technology provides increased confidence to operational teams by reducing nuisance alarms.

Early Intervention

Swift detection of 3rd party activity allows prevention of accidental damage to a pipeline.

Intrinsically Safe

The solution has no moving parts and in addition requires no power or electronics in the field.

Improved Decision Making

Providing precise, real-time and actionable information at all points on the grid. Therefore facilitating rapid and focused decision making to improve management at all points on the pipeline.

Cost-effective Implementation

Reduced overall cost of deployment by utilising existing telecoms infrastructure along pipelines – working closely with telecoms/SCADA installer.

Leak Detection

Early detection of leaks can prevent environmental and reputational damage.

Advanced Fiber Optic Sensing Solutions: Pipeline

Seismic Activity / Landslide / Rockfall Detection

Utilising the latest generation optical fibre technology together with advanced signal processing, operators are alerted to major events that have the potential to cause damage to pipeline infrastructure.

With the ability to pinpoint the source of disturbance with unrivalled accuracy, clients can quickly establish the potential impact on their operations and consequently take appropriate actions to mitigate risk.

Third Party Interference (Manual and Vehicular)

Utilising Bandweaver’s Distributed Acoustic Sensing (DAS) technology enables operators to be aware of events that may cause damage to pipeline infrastructure. These include damage to the pipeline from accidental or deliberate digging, tapping, and other malicious attacks.

The system can identify the exact location of a 3rd party event and can detect both vehicles and personnel in close proximity to the pipeline. Therefore ensuring early action can be taken before the pipeline is damaged to minimise potential loss.

PIG Tracking (Pipeline Inspection Gauge)

Our solutions can track Pipeline Inspection Gauge (PIG) as they move through the pipeline, quickly alerting operators to their location and providing real time alarm events to a stalled PIG.

We can track multiple PIGs in the same pipeline, providing accurate location data that can be invaluable for a newly constructed pipeline or a pipeline that has been infrequently inspected.

Leak Detection

Bandweaver’s Leak Detection Solutions (LDS) are suitable for both gas and liquid pipelines and can quickly and accurately identify the location of a leak utilising Distributed Temperature Sensing (DTS) and/or Distributed Acoustic Sensing (DAS) solutions.

With market leading location accuracy, operators can quickly respond to a pipeline leak, avoiding costly environmental, financial and reputational damage.

Third Party Interference (Manual and Vehicular)

Utilising Bandweaver’s Distributed Acoustic Sensing (DAS) technology enables operators to be aware of events that may cause damage to pipeline infrastructure. These include damage to the pipeline from accidental or deliberate digging, tapping, and other malicious attacks.

The system can identify the exact location of a 3rd party event and can detect both vehicles and personnel in close proximity to the pipeline. Consequently, this ensures early action can be taken before the pipeline is damaged to minimise potential loss.

Application areas include

- Applicable for multiple pipeline types including:

- Oil, gas and petrochemical

- LNG

- Water

- Mining slurry

- Third Party interference / Pipeline intrusion detection

- Leak detection

- PIG tracking

Bandweaver is ISO 9001 certified and undergoes a rigorous continuous improvement program and tests all of its products to leading international standards.

For the pipeline sector, Bandweaver tests according to both industry standards and customer specific testing. All of our classification engines undergo extensive testing and qualification and have scored highly in independent technology comparison tests.

In addition to our industrial monitoring customers, Bandweaver is also a leading international supplier into the telecoms industry which has some of the most stringent quality and reliability requirements.

Bandweaver has extensive in-house environmental testing facilities but also utilises leading 3rd party testing houses for independent verification and approvals.

-

- Extensive environmental testing on all products

- Components to meet telecom standards > 31 years MTBF

- Products are designed for low maintenance and cost of ownership (e.g. fan free design..)