Linear Heat Detection Solutions

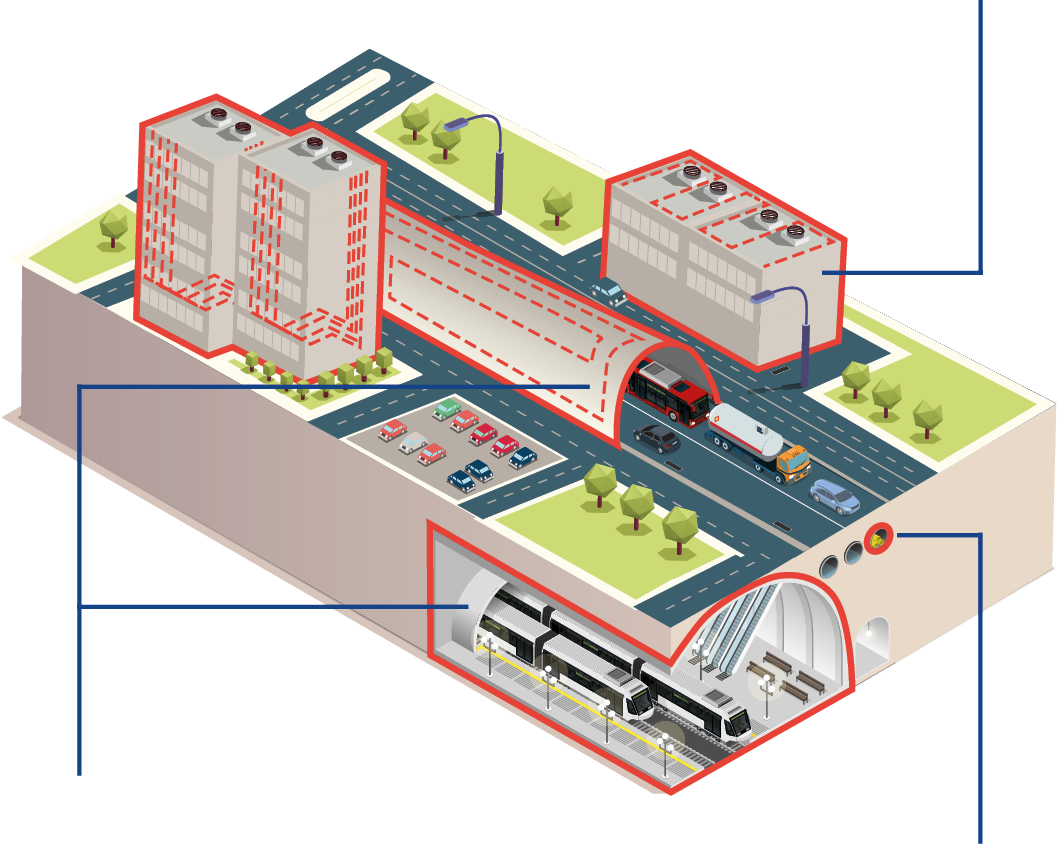

Bandweaver’s range of fiber optic monitoring systems are designed specifically to enhance the fire safety of critical infrastructure and personnel.

We provide solutions for fire detection utilising linear heat detection technology, monitoring environments over a long range distance (linear assets), typically in special hazard environments.

LHD systems can detect a fire anywhere along the length of the linear heat sensing cable, over a distance of several kilometers. Bandweaver utilises fiber optic distributed temperature sensing, one of the key technologies available within this field.

Combined with our smart software and services, this solution provides operators with the right information at the right time.

Whether the asset is in a remote location or a busy inner city, Bandweaver’s solutions enable swift decision making and help to minimize damage and consequently avoid catastrophic failure and to reduce financial, environmental and reputational risk.

Intelligent Insights

Some of the conventional linear heat detection systems that have typically been used include, digital cable based, analog cable, pressurised tube and multipoint detection.

There are some significant advantages of utilising fiber optic sensors over conventional technologies, these include:

Early Detection

Earlier identification of the rate of rise and so can detect earlier than other technologies which rely on discrete trigger points at a higher temperature.

Truly Distributed

Due to the distributed continuous nature of the fiber, there is complete coverage of the asset with no gaps.

Versatile

Fiber optic sensing technology is resistant to electromagnetic interference and is intrinsically safe, enabling it to be used in a wide variety of installations.

Low maintenance

Completely passive, corrosion free, no apertures, joints or moving parts, ensuring a very low maintenance option.

Advanced Fiber Optic Sensing Solutions: Fire

Linear Heat Detection

Buildings

Monitoring of industrial buildings, factories, warehouses, refrigerators, car parks, hangers and other large facilities Fiber optic Linear Heat Detection makes a good complement or alternative to other technologies such as beam detectors, aspiration systems and point smoke sensors.

Transformers, Switchgear, Busbars And Cable Trays

Fiber optic linear heat detection systems are very effective at monitoring electrical assets within industrial facilities and detecting temperature hot spots before they become a potential fire event.

Roads and Rail Tunnels

Linear Heat Detection

Fiber optic linear heat detection systems have established themselves as the number 1 effective solution for safe and effective monitoring for road and rail tunnels. with up to 10km range per system, this is an extremely cost effective and reliable technology for fire detection and prevention in tunnels.

Ventilation Control

Fiber optic based linear heat detection can provide absolute temperature values along the length of the entire asset. This can be integrated into the operators ventilation control system, allowing them to use this information both in normal operations and under fire conditions.

Underground Power Cable Monitoring

In addition to condition monitoring, fiber optic DTS can be utilised as a linear heat detection system.

Either installed on the cables or in the apex of the tunnel they, provide early warning of any potential hot spots in the electrical cables.

- Tunnels – Road, Rail and metro

- Car parks

- Conveyor belts

- Aircraft hangers

- Cable trays and culverts

- Large industrial facilities

- Tank farms

- Warehouses and freezers

- Escalators

Reliability and Approvals

Bandweaver is ISO 9001 certified and undergoes a rigorous continuous improvement program and tests all of its products to leading international standards.

For the fire & security sector, Bandweaver tests according to both industry standards and customer specific testing. Approvals for the fire sector include international standards (e.g. EN 54 part 22) and country specific standards.

In addition to our industrial monitoring customers, Bandweaver is also a leading international supplier to the telecoms industry which has some of the most stringent quality and reliability requirements.

Bandweaver has extensive in-house environmental testing facilities but also utilizes leading 3rd party testing houses for independent verification and approvals.

-

- Extensive environmental testing on all products

- Components to meet telecom standards > 31 years MTBF

- Products are designed for low maintenance and cost of ownership (e.g. fan free design …)