SMART ENERGY GRID PROTECTION

Bandweaver has worked together with customers and technology partners in the power sector for more than 18 years to develop condition monitoring solutions for the intelligent grid.

When used alongside a proactive maintenance approach, our state of the art sensing systems and intelligent software provide the operator with the right information at the right time to make decisions that help you to reduce planned and unplanned maintenance, to avoid catastrophic failure and to effectively manage your risk.

Intelligent Insights

Bandweaver’s extensive range of sensors and integrated smart software solutions, combined with our ability to interface with industry standard communication protocols, enables us to tailor the system to meet your specific needs.

Greater Visibility

Improved situational awareness, increased compliance, reduced risk of fines and lower insurance premiums.

Smart Management

Greater return on investment and delayed capital spending by maximising component lifetime and preventing unnecessarily maintenance.

Cost-effective Implementation

Reduced overall cost of deployment by utilising existing telecoms infrastructure for sensing elements.

Enhanced Security

Reduced risk of malicious or accidental third party intrusion (TPI) by monitoring and alarms at all points on the grid, including associated perimeters, entry and access points.

Improved Decision Making

Providing precise, real-time and actionable information at all points on the grid, facilitating rapid and focused decision making to improve management of grid assets.

Advanced Fiber Optic Sensing Solutions: Power

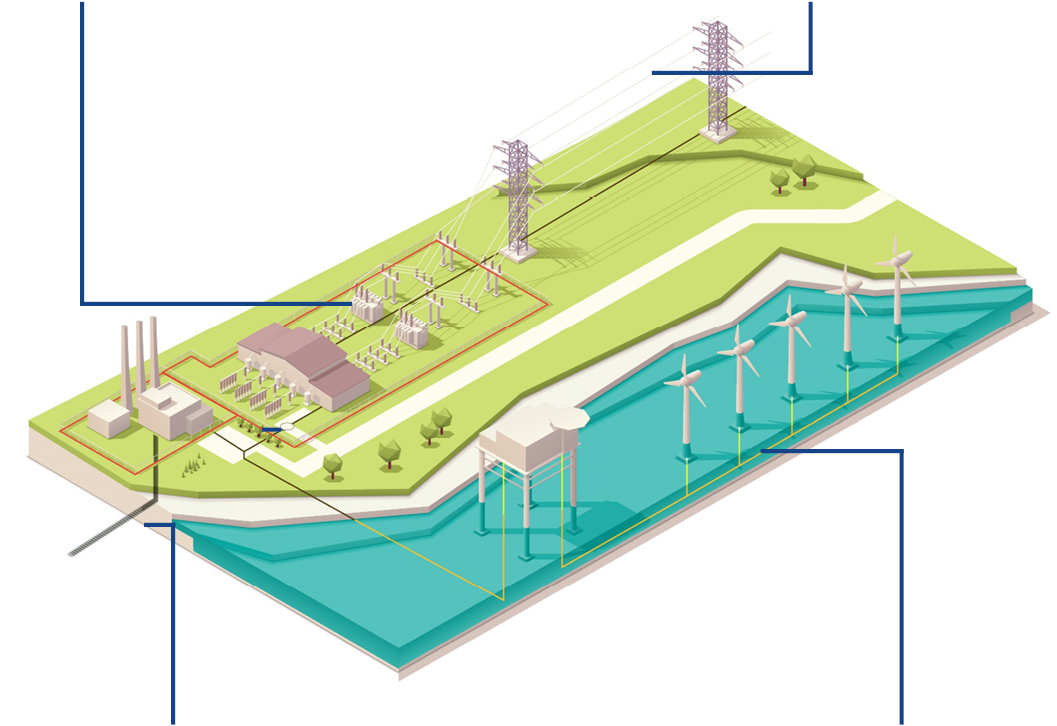

Substation Asset Monitoring

Distributed Temperature Sensing (DTS) and Distributed Acoustic Sensing (DAS) provide efficient condition monitoring and protection for a number of assets within the utility and substation environment. This includes assets such as:

- Gas Insulated Switchgear (GIS)

- Transformer monitoring

- Busbar hotspot detection

- Cable trays and ducts

Overhead power Line Tampering Detection

DAS can make use of existing infrastructure through monitoring fiber optic cable already installed (e.g. OPGW).This can apply to both transmission and distribution infrastructure. Applications include:

- Theft detection and prevention of cables and structural elements

- Anti-tampering and sabotage detection

Under Ground Cable Fault Detection and Real Time Thermal Rating (RTTR)

DTS has become an established tool for condition monitoring and protection of underground cables. It provides a complete thermal profile of the cable allowing the operator to accurately locate and hot spots and potential causes of failure.

Bandweaver’s RTTR system allows the user to accurately model the thermal environment and specifically the cable conductor. This allows operators to safely manage the capacity within the network. This can be critical to plan for peak loads and emergencies but increasingly is allowing operators to add additional capacity and increase ratings.

DAS also provides third party interference (TPI) and prevention of both malicious tampering and also accidental damage from construction equipment. There is also potential for monitoring and evaluation of partial discharge and other vibration condition monitoring.

Offshore Subsea Cable Protection

DAS can monitor the spare fiber optic cores typically incorporated in subsea cables to provide protection for the subsea cables. Key applications include:

- Span monitoring location and mitigation

- Vessel location and detection of anchor drag

- Detection and monitoring of sea floor debris and other hazards

- Cable movement and location on the sea floor

- Partial discharge monitoring

Below are some of the applications within the power sector that utilize Bandweaver’s range of distributed temperature and acoustic fiber optic sensors and intelligent software solutions. For the power sector, Bandweaver has developed the Real Time Thermal Rating (RTTR) software which has dynamic cable rating algorithms developed according to CIGRE and IEC60287.

Applications

- Power cable intrusion and detection

- Tampering of overhead lines

- Third party intrusion prevention of buried cables

Bandweaver is ISO 9001 certified and undergoes a rigorous continuous improvement program and tests all of its products to leading international standards.

For the power sector, Bandweaver tests according to both industry standards (IEC, CIGRE) and customer specific type testing. These types tests include environmental, EMC test results and specific product qualifications. Reports can be made available on request.

In addition to our industrial monitoring customers, Bandweaver is also a leading international supplier to the telecoms industry which has some of the most stringent quality and reliability requirements.

Bandweaver has extensive in-house environmental testing facilities but also utilizes leading 3rd party testing houses for independent verification and approvals.

-

- Extensive environmental testing on all products

- Components to meet telecom standards > 31 years MTBF

- Products are designed for low maintenance and cost of ownership (e.g. fan free design …)