Industrial fires cause extensive damage across the globe each year, with the highest-risk fires found in environments where detection is most difficult. Those industries most at risk of insufficient detection are oil and gas, power, chemical processing, mining, and transport.

The consequences of delayed detection are serious, from risk to life, equipment damage, and environmental impact. This is why in many fire scenarios, the difference between minor damage and catastrophe less than 2 minutes.

Understanding detection challenges

Traditional fire detection systems operate at the mercy of their environments. They’re often compromised by environmental complexities such as dust, humidity, corrosive materials and smoke layering. Across widespread distributions such as cable tunnels and pipelines, traditional systems struggle to operate effectively over long distances in inaccessible zones. Variable airflow contributes further to these detection challenges by dispersing smoke unpredictably.

These are just some of the many ways conventional fire detection technologies fall short:

Smoke Detectors:

Smoke detectors predominantly rely either on beam detectors or air samples (aspiration detactors) reaching the detector, meaning in poorly ventilated areas or open spaces they may fail to detect smoke or are completely blocked in areas where there is dirt or particles in the air and cover the lenses or block the ducts. Additionally,, smoke detectors are more likely to raise false alarms in environments where they are bombarded by dust, fumes or aerosols. Over time this exposure can build up, blocking sensors and stopping detection entirely.

Flame Detectors:

These detectors require a line of sight to the flames to detect a fire. This has its downfalls, as flame detectors are rendered ineffective in the event of an early-stage fire where flames are not visible yet or have been concealed. Flame detectors have the same vulnerability as smoke detectors, where they can become blocked by dust and debris in the surrounding environment.

Thermal Cameras:

Thermal cameras are often more effective for detecting large heat sources, not subtle anomalies or spikes in temperature – meaning fires may not be detected until it’s too late. As with the previous detection methods, thermal cameras are also at risk of being blocked or damaged by environmental factors such as fog, controlled smoke clouds, or obstructions and they are also range limited and not suitable for larger areas .

The solution: Distributed Temperature Sensing (DTS)

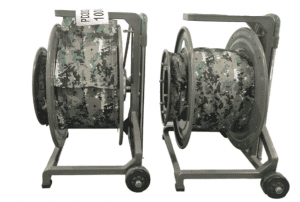

DTS uses fiber optic cables as linear heat sensors, continuously monitoring temperature along the entire length of the cable. A laser pulse is sent along the fiber, using backscatter to analyse and determine the temperature at every point along the fiber. This enables real-time thermal monitoring over widespread distances.

Compared to traditional systems, Distributed Temperature Sensing has countless benefits such as continuous coverage with no blind spots, and immunity to environmental interference such as dust, exhaust fumes and humidity. DTS provides ultra early detection, identifying temperature spikes as soon as they appear, with accuracy within 1°C and 1 meter. To further enhance efficiency, DTS uses no moving parts meaning low maintenance and high reliability.

Inside the FireLaser system

FireLaser is a purpose-built solution for industrial and hazardous environments, consisting of fiber optic linear heat detection, precise location-based alerts, configurable temperature thresholds, and integration-ready functions for fire suppression, SCADA and ventilation.

The reason FireLaser is so effective is because of its high standards of monitoring even in harsh, confined, or hazardous environments. Long cable runs make the system cost-effective when covering large infrastructure as well as its resistance to environmental wear and electromagnetic interference. Explosive environments are sensitive to electronic interference making monitoring systems complex to implement, but FireLaser’s fiber is completely passive with no electronics in the field, making it the perfect solution.

Benefits for high-risk industries

Fiber optic linear heat detection is the ideal solution for numerous high-risk applications such as:

Oil and gas/chemical plants:

Fiber optic can detect heat build-up in cable trays, tank farms and processing areas, minimising the risk of explosions from equipment overheating – a threat that often goes undetected by traditional monitoring systems.

Power cables and infrastructure:

Monitoring power cable tunnels, busbars and substation infrastructure for overheating with fiber optic is an incredibly effective way of reducing blackouts or downtime caused by electrical fires.

Road and Rail Tunnels:

In tunnel fires is of the essence; fiber optic is able to spot fires before smoke reduces visibility or evacuation becomes unsafe or impossible. FireLasers integration with other systems also allows for ventilation or suppression systems to be triggered instantly.

Warehousing/logistics/factories:

FireLaser monitors racking, electrical cabinets or large storage areas with minimal infrastructure, providing vital fire detection to protect assets.

Data centres and battery storage facilities:

Critical systems are vulnerable to cable or battery overheating. fiber optic fire detection protects these systems by detecting the earliest signs of overheating through configured temperature thresholds.

Partnering with Bandweaver for the future of high-risk industrial monitoring

FireLaser is backed by years of successful deployments, with applications in major infrastructure projects across the globe and a proven track record in critical, hazardous environments.

Our partners are set up for success with full support through our partner portal, including comprehensive training and datasheets to aid easy installation and integration into existing alarm infrastructure. The system is designed for a long lifecycle with low maintenance, using passive components that mean fewer points of failure.

Time for a change

In high-risk environments, every second counts so it’s time to deviate away from traditional systems that are often too slow or unreliable when conditions are most dangerous. FireLaser offers fast, accurate and scalable fire detection where it matters most.

Want to help reduce fire risks and improve safety across critical infrastructure? Speak to our team or find out how you can become a partner: https://www.bandweaver.com/about-bandweaver/partners/