Elotec Finland has won the Snellman Petfood Factory project, where our FireLaser linear heat detection system will be installed with 2 km of fibre optic cable. The system provides continuous, real-time temperature monitoring, giving the facility reliable early-warning fire detection across critical production areas.

“This system gives our operators instant insight into any hot spots along the production line,” says project manager Peter. “It’s all about keeping the factory safe while ensuring production runs smoothly.”

This project demonstrates our ongoing partnership with Elotec and our commitment to protecting vital industrial facilities.

About Bandweaver

With an installed base of over 80,000km and 9,000 systems worldwide, Bandweaver’s vision is to be the first choice for integrated distributed fiber optic sensing solutions across the globe. Since 2002, Bandweaver has been committed to delivering reliable, innovative, client-centric, and value-added products and services, via a dedicated and talented team of people.

Bandweaver manufactures and distributes advanced fiber optic monitoring sensors and integrated technologies, enabling customers to monitor, secure and keep personnel and critical assets safe.

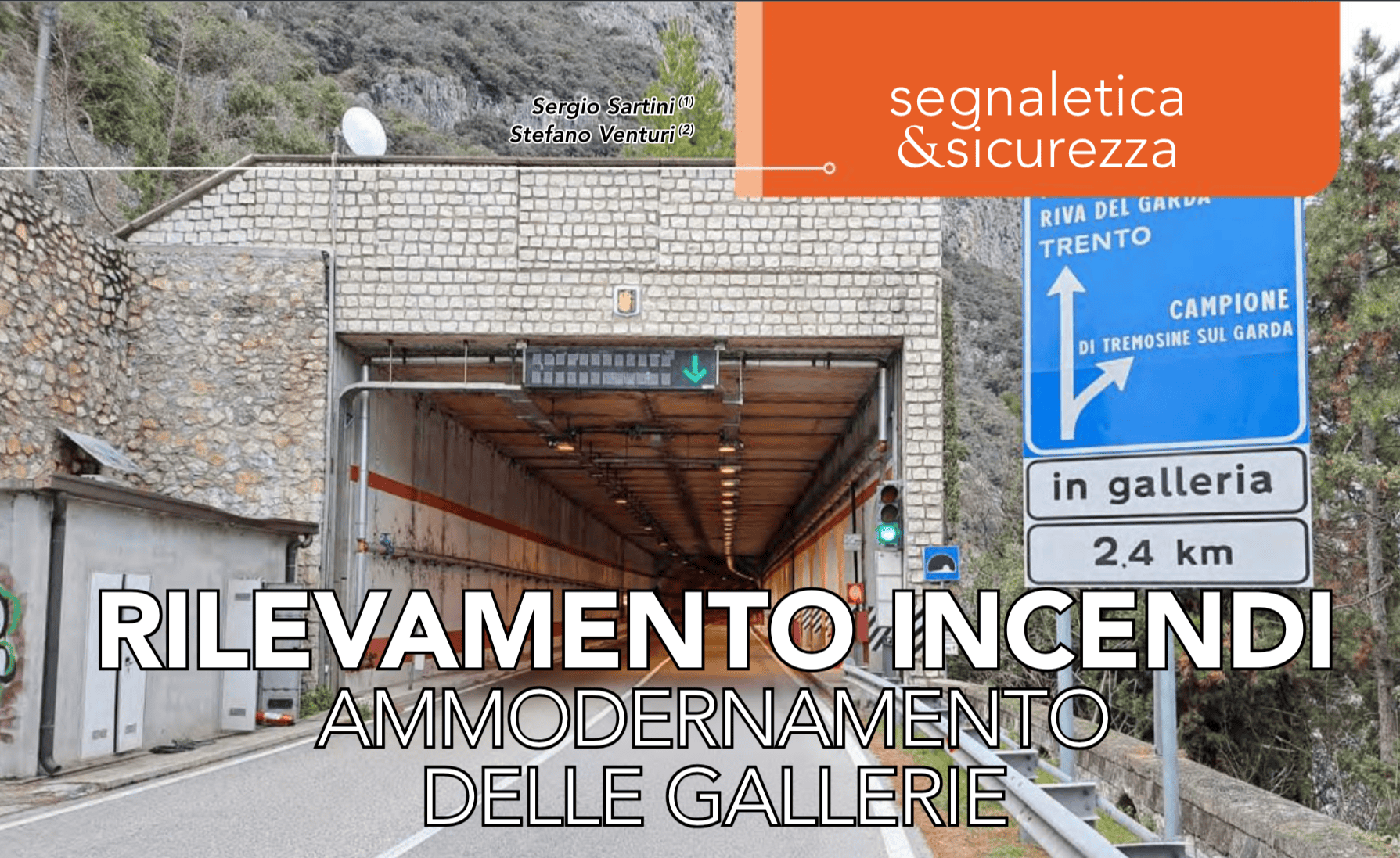

Bandweaver’s solutions have been utilised for multiple applications, including road and rail tunnels and spurs as well as facility buildings, power infrastructure, escalators, and stations.

Utilising the latest technologies, Bandweaver provides solutions for Security, Fire, Power, and Pipelines.

For further information please contact our global team at info@bandweaver.com