The Scenario

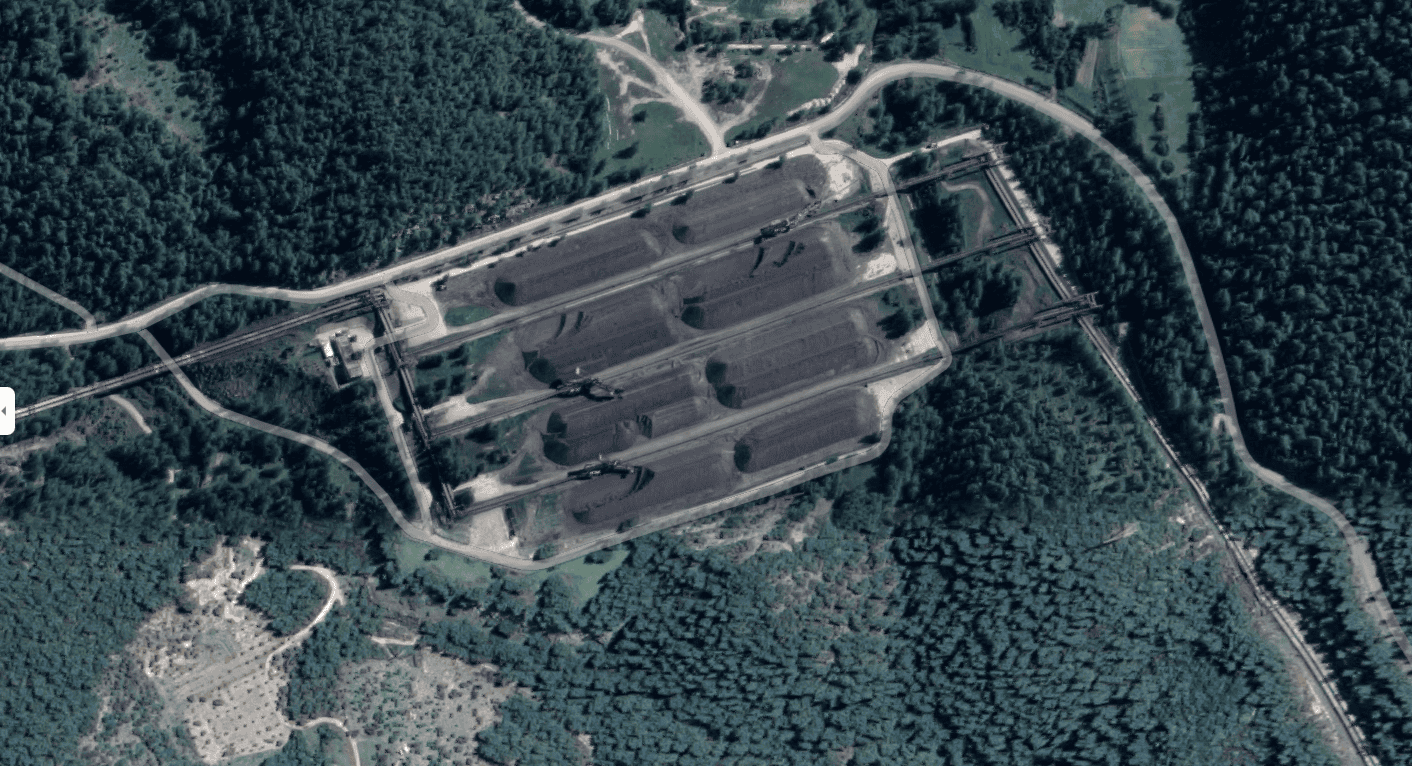

Yeniköy is a 420 Megawatt MW coal-fired power station in Yeniköy, Muğla, Turkey and is owned by Limak- IC İçtaş. The site first became operational in 1986 with a current annual nominal production capacity of 2,730,000,000 KWh.

Yeniköy thermal plant and neighbouring and Kemerköy power station are classified as critical power infrastructure. Both, plants involve the transport and processing of a highly flammable product – domestic lignite. With more than 20km of belts to be monitored, advanced detection and visualisation was required to effectively protect the site.

Every year, 10 million tonnes of coal are transported through the on-site conveyor belt system, making it a critical component in the operation of the power station.

Client Requirements

The Yeniköy Kemerköy conveyor belt is a key part of the value chain to the client’s business. This plant must be able to operate over long periods of time with minimum disruption to production demands.

A solution was required to ensure the effective management of temperature events within this critical area, for detecting local overheating of equipment and providing early fire detection capability, within the client’s allocated budget.

The solution had to be cost effective in terms of cost of ownership, throughout the retrofit installation and including lifetime support costs.

The required solution needed to ensure that the client could possess and own the optimal solution in terms of reducing risk and minimizing ongoing maintenance costs.

What Did We Do?

The end user initially trialled thermal cameras on the site, however the performance was not satisfactory and did not adequately fulfil the requirements. BTS Yangın worked with the customer to design a fiber optic Linear Heat Detection (LHD) system based on Bandweaver’s FireLaser DTS system. After demonstrations from two fiber optic linear heat detection providers, the project was awarded to BTS Yangın, utilising Bandweaver’s FireLaser distributed temperature sensing solution.

A single 4 channel / 10km FireLaser unit was installed, offering the end user up to 40km of monitoring capability. For this particular application, 714 zones were configured, measuring 30m in length per zone over a total of 21.4km.

The FireLaser’s smart alarms were configured to detect maximum temperatures of 57-61.5°C, as well as a rate of rise of rise 5°-7°C. Using both variables, the system ensured that operators would be alerted should the system overheat in a range of conditions.

To provide a complete overview of the site’s operation, FireLaser was integrated with Panasonic CCTV via FireLaser’s built-in relay outputs. Bandweaver’s MaxView software platform was also used for advanced visualisation of the site and the fiber optic sensing system.

Detection of hot roller

For conveyor belts one of the key maintenance issues is the issue of roller failure and subsequent heating. When the bearing in a roller fails, typically resulting in high levels of friction which will cause the bearing to become very hot and lead to fires. As well as fire detection, the FireLaser linear heat detection system was also able to detect heating in rollers along the conveyor, prior to an ignition event.

In the event of an alarm, technical staff on site can be alerted by the operator in the control room to check the sensing cable with a thermal camera within the zone that is in a state of alarm. The heated cylinder can thus be detected within any 30-metre zone in a very short time. By using the professional thermal camera, the temperature can be understood almost precisely, and appropriate action taken.

Before the FireLaser DTS system was installed, there were even rollers that had become embers. However, with this early detection system, mechanical problems can be detected quickly after the early alarm detection, and heating effects minimised. Once the conveyor is stopped, the roller can be replaced and the conveyor normal operating mode in a short time.

Benefits To the Client

The Bandweaver system complied with the operator’s high specification requirements. Some of the key following benefits and advantages to the end user include:

- Early detection of even a small fire: Bandweaver LHD systems are approved to operate with a measurement time of 5 seconds which is considerably quicker than the alternatives. With the smart alarms (including rate of rise and deviation alarms), the system can detect fires at a very early level without risk of false alarms.

- Complete Coverage: The distributed nature of the fiber optic system provides measurements every 1m along the length of the cable providing complete and continuous coverage with no blind spots or gaps in the protection.

- Low Cost of Ownership: Fiber optic cables are completely passive and have no moving parts, they are non-corrosive and immune to electromagnetic interference and typically have lifetimes of more than 30 years and so carry a very low cost of ownership and no maintenance.